Modal fabric shows up in nearly everything now, underwear, pajamas, bed sheets, and even workout wear.

It’s often marketed as an eco-friendly upgrade to cotton or synthetics, promising comfort, breathability, and a smaller footprint.

But modal sits in a gray area. It comes from trees, but the process that turns that wood into fabric depends heavily on chemistry.

The question of whether modal is toxic doesn’t have a simple yes or no answer; it depends on how it’s made, who makes it, and what chemicals are involved along the way.

Many of us choose fabrics for how they feel, not realizing that the same softness we love can come from manufacturing systems that harm workers or the environment.

What Is Modal Fabric?

Modal is a semi-synthetic fabric made from the pulp of beech trees. It’s part of the rayon family, which also includes viscose and lyocell (sold under names like TENCEL™).

Technically, modal starts with natural cellulose but needs chemical processing to become wearable fibers.

Its appeal is easy to understand. Modal feels smooth, drapes beautifully, and resists shrinking or fading. It’s breathable, durable, and keeps its shape even after repeated washes.

That’s why it’s so common in everyday essentials like underwear, activewear, and bed linens.

Its environmental reputation comes from its source material. Beech trees grow quickly, need little irrigation, and can thrive without pesticides.

Within the rayon family, modal sits between two opposites:

- Viscose rayon uses harsher chemicals and older, open-loop systems that release toxins.

- Lyocell (TENCEL™) uses a modern closed-loop process that safely recycles almost all its solvents.

Modal combines the comfort of both but doesn’t always match Lyocell’s cleaner production standards.

How Is Modal Fabric Made?

To understand whether modal is toxic, it helps to see what actually happens between the forest and the finished fabric. Beech trees don’t naturally turn into soft fiber.

They have to go through a long chemical process that completely changes their structure.

-

Step 1: Harvesting and pulping: Manufacturers start by harvesting beech trees and turning the wood into cellulose pulp. At this point, it’s still a natural material.

-

Step 2: Chemical dissolution: To turn that pulp into fiber, it’s dissolved using strong chemicals, most commonly sodium hydroxide and carbon disulfide. These reagents break down the wood’s structure into a thick, viscous solution.

-

Step 3: Fiber formation: The liquid cellulose is pushed through tiny holes called spinnerets, forming long, thin filaments. These filaments solidify into fibers when they hit a chemical bath.

-

Step 4: Chemical safety risks: This stage raises the biggest environmental and health concerns. Carbon disulfide is a neurotoxin that can seriously harm factory workers if exposure isn’t controlled, and improper disposal pollutes the surrounding air and water.

-

Step 5: Finishing and treatment: After the fibers are formed, they’re washed, bleached, dyed, and softened to create the final look and feel. Each of these steps can introduce additional residues if not managed carefully.

Closed-loop vs. open-loop systems

Some manufacturers use a closed-loop system, capturing and reusing up to 95% of solvents instead of releasing them.

This limits pollution and protects workers. Brands using this method often mention certifications like OEKO-TEX or Lenzing’s Eco Soft Technology.

Others use open-loop systems, where chemicals are discarded after one use. This cheaper approach causes most of the environmental and health issues linked to modal production.

That’s why asking “Is modal toxic?” is really about which modal you’re talking about. The raw material itself isn’t harmful; it’s the production practices that determine whether the final fabric stays safe and sustainable.

Types of Modal Fabric and Their Toxicity

Not all modal fabrics are equally safe. The difference lies in how they’re made and whether harmful chemicals are properly contained or released during production.

-

Standard Modal: Made with sodium hydroxide and carbon disulfide, which can harm workers and the environment if unmanaged. The final fabric is usually safe, but uncertified production raises pollution risks.

-

MicroModal: A finer, softer version made through the same process. Comfortable to wear, but toxic exposure depends on factory conditions; safe if closed-loop, concerning if not.

-

Modal Blends: Combined with cotton, spandex, or polyester for flexibility or strength. Not more toxic by itself, but synthetic blends may shed microplastics and are harder to recycle.

-

TENCEL™ Modal (Lenzing Modal): Produced in a closed-loop system that recycles 99% of chemicals. Certified non-toxic and environmentally safe, the best choice for skin contact and sustainability.

-

Modal-Lyocell or Modal-Cupro Blends: Blends using safer fibers like lyocell or cupro are generally low in toxicity. Still, certification matters since the modal portion can vary in quality.

Worst Toxic Fabrics and Safer Alternatives

Some fabrics hide harsh chemicals or toxic treatments that affect both your health and the planet.

Understanding which ones to avoid and what to choose instead helps you build a wardrobe that feels safer, lasts longer, and aligns with conscious living.

1. Polyester

Polyester is a petroleum-based synthetic fiber produced with high heat and chemical treatments. It sheds microplastics with every wash, contributing to ocean pollution.

While durable and wrinkle-resistant, its inability to breathe traps heat and moisture against the skin, which can lead to irritation. It’s also non-biodegradable and environmentally persistent.

2. Nylon

Nylon is another petroleum-derived fiber requiring energy-intensive manufacturing and chemical solvents. Though strong and flexible, it often traps heat and moisture, creating discomfort.

Dyeing nylon requires more chemicals than natural fabrics, producing waste and potential toxins.

It also releases microfibers during washing, polluting waterways and affecting marine life through long-term environmental buildup.

3. Acrylic

Acrylic fabric mimics wool but originates from acrylonitrile, a known irritant and potential carcinogen.

Its production process involves volatile compounds harmful to workers and the environment.

Acrylic also tends to pill, shedding small fibers into the air and water. Over time, these particles contribute to microplastic pollution and can trigger skin sensitivity in some wearers.

4. PVC / Vinyl

PVC, or polyvinyl chloride, is heavily plasticized with phthalates that can leach out over time. These plasticizers are hormone disruptors linked to various health risks.

Used in faux leather and coated fabrics, PVC also releases toxic byproducts during production and disposal. It’s one of the least sustainable and most chemically hazardous materials.

5. Conventional Rayon (Viscose)

Viscose rayon is made from wood pulp dissolved in chemicals like carbon disulfide, which harms factory workers and ecosystems.

The process releases toxic waste into waterways if unmanaged. While soft and breathable, uncertified viscose remains a major pollutant.

Cleaner options exist, but low-cost viscose from unregulated facilities poses clear health and environmental risks.

6. Acetate and Triacetate

These semi-synthetic fibers come from wood pulp treated with acetic acid and other chemicals.

While smooth and shiny, their production releases volatile organic compounds (VOCs) that degrade air quality.

They’re often finished with additional coatings for durability, which adds more chemical exposure. Acetate also breaks down poorly, making it less sustainable long-term.

7. Treated Cotton

Non-organic cotton absorbs large quantities of pesticides during cultivation. Post-harvest, many cotton fabrics are treated with wrinkle-resistant finishes containing formaldehyde and other chemicals.

These treatments can irritate skin and emit fumes when heated. Though breathable, untreated or organic cotton is a far safer alternative for everyday wear, especially for sensitive or allergy-prone individuals.

8. Spandex (Elastane)

Spandex is valued for stretch and recovery, but requires dimethylformamide (DMF), a toxic solvent, during production.

Prolonged worker exposure to DMF can cause liver damage. While spandex makes clothes fit well, it’s not biodegradable and releases microfibers over time.

9. Water-Repellent & Stain-Resistant Fabrics

These fabrics rely on per- and polyfluoroalkyl substances (PFAS), also known as “forever chemicals.”

PFAS coatings repel water and stains but don’t degrade, leading to their accumulation in the body and environment.

Linked to hormone disruption and cancer, these finishes make clothing convenient but risky. Opting for untreated or PFC-free options minimizes long-term exposure and harm.

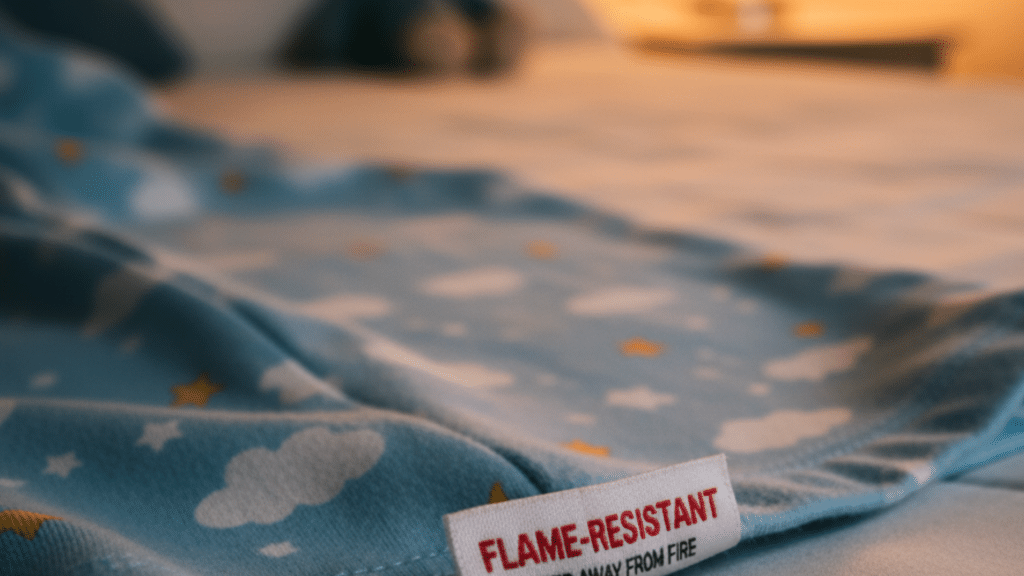

10. Flame-Retardant Textiles

Used in sleepwear, upholstery, and workwear, flame-retardant fabrics often contain brominated or chlorinated compounds.

These chemicals resist washing out, persisting in indoor air and dust. Long-term exposure may affect hormone balance and development.

Natural fibers like wool provide inherent flame resistance without synthetic additives, offering a safer, low-chemical alternative for households and clothing.

Safer Alternatives for Everyday Use

Choosing safer fabrics doesn’t mean giving up comfort or style. It’s about picking materials made responsibly, free from unnecessary chemicals, and built to last.

- Organic Cotton: Grown without pesticides or synthetic fertilizers, it’s gentle on the skin and environment. Breathable, soft, and biodegradable, it remains one of the safest everyday fabrics.

- Linen: Made from flax that requires minimal water or treatment, linen naturally resists bacteria and odors. It’s durable, cool in warm weather, and improves with every wash.

- Hemp: A fast-growing, low-impact crop that enriches soil and needs no chemicals. The fiber is strong, breathable, and naturally antimicrobial, perfect for daily wear.

- Organic Wool: Free from chemical dips or flame retardants, organic wool is naturally temperature-regulating and long-lasting. It’s a renewable, biodegradable option for cooler climates.

- Recycled Natural Fibers: Made from recovered cotton, linen, or wool, these fabrics reduce waste and energy use. They maintain comfort and quality while supporting circular, sustainable production.

How to Choose Safer Fabrics

Shopping for non-toxic fabrics doesn’t have to be complicated. A few reliable markers can help you recognize safer options, even when labels or marketing make things confusing.

| Step | What to Do | Why It Matters |

|---|---|---|

| 1. Check Certifications | Look for OEKO-TEX, GOTS, or Bluesign labels. | Confirms fabrics are tested for harmful chemicals. |

| 2. Prioritize Transparency | Choose brands that share sourcing and production details. | Honest brands usually follow safer, sustainable practices. |

| 3. Ask About Fiber Sources | Check if wood-based fabrics use FSC or PEFC-certified pulp. | Ensures responsible forestry and cleaner processing. |

| 4. Avoid Heavy Dyes & Finishes | Pick lighter or undyed fabrics whenever possible. | Reduces exposure to harsh dyes and chemical coatings. |

| 5. Start With the Basics | Begin replacing items like bedding or underwear. | Safer swaps are easier to manage and most impactful. |

| 6. Wash Before Wearing | Wash all new clothes once or twice before use. | Removes surface chemicals, dyes, and residues. |

| 7. Trust Proven Brands | Support brands with visible certifications and data. | Transparency signals safer, cleaner manufacturing. |

Conclusion

Modal fabric isn’t automatically toxic, but its safety depends on how it’s made. The fiber itself comes from natural cellulose, yet the chemicals used during production can vary widely between manufacturers.

The risks arise from poorly regulated factories that release untreated chemicals or skip purification steps.

The truth is, no fabric is entirely impact-free, but informed choices make a measurable difference. Choosing certified modal, organic, and natural fibers and transparent brands protects both your health and the environment.

With a few mindful changes, your closet can hold fabrics that feel good, look good, and are genuinely better for you.